UMPB-8P bitumen modification unit is designed for preparation of modified bitumen by adding polymers. The unit grinds and homogenizes polymers in bitumen, reducing PMB preparation time.

The unit can be used at road top production and repair, water-proofing material production and soft roofing material production facilities.

The unit can be operated either outdoors under canopy or indoors with forced ventilation. The unit may be operated in ambient temperature from +5°Сto +40°С.

Specifications

1 Capacity, m3/hour, minimum 6

2 Bitumen consumption, ton/hour 6

3 Polymer consumption, kg/hour 600

4 Plasticizer consumption, kg/hour, max 750

5 Operation mode

Continuous

6 Power consumption, kW 90

7 Power 380 V/50 Hz

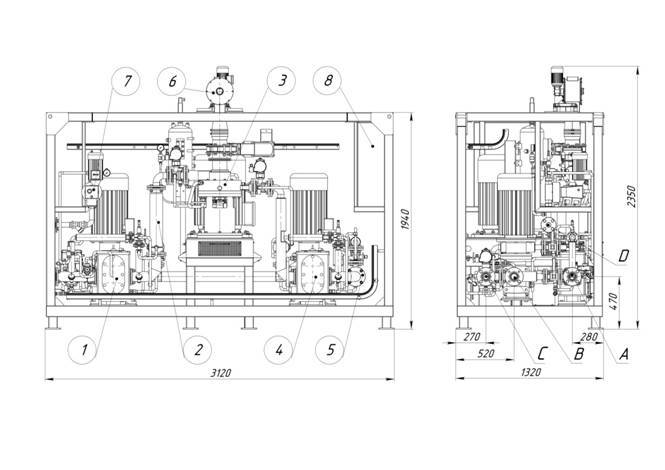

8 Max dimensions, mm

- length 3120

- width 1320

- height (without screw conveyor) 2350

9 Max weight, kg 2700

Principle of opertaion

A – input (bitumen supply) DN50; B – bitumen return line to bitumen tank DN50;

C – modified bitumen output DN50; D – plasticizer input DN25

Bitumen heated to operating temperature is supplied to the unit from the tank by an external bitumen pump through pipeline “А”. Part of the supplied bitumen returns to the tank through pipeline “B”. The bitumen pump pos. 1 takes the required amount of bitumen from the line A, mixing it with plasticizer supplied by pump pos. 7. The bitumen with plasticizer are uniformly mixed, passing through hydrodynamic mixer pos. 2 and go to the colloid mill pos. 3, where powder or pelletized SBS polymer is added to the mix by a weight portioner pos. 6. The rotor of the mill rotating at 2950 RPM grinds the polymer in the mix and homogenizes the product.

Bitumen pump pos. 4 takes the product from the mill and charges it into the second hydrodynamic mixer pos. 4, where the modified bitumen is stabilized. The modified bitumen is then supplied to storage through pipeline C.

The unit is controlled from the control cabinet pos. 8. The following components are installed in the control cabinet: controller, communications for starting and stopping motors and pneumatic valve controls, electromagnetic relays, control and motor circuit protection devices. The control system allows operation either in manual or automatic modes.

Pipelines and assemblies of the unit are insulated by jackets for heating with oil before operation.

An external source of compressed air is required for operation of pneumatic valves.

Screw conveyor for supply of polymer to the portioner is optional.

TYPICAL EQUIPMENT PLACEMENT AT MODIFIED BITUMEN PRODUCTION SITE